Induction Hardening

Cincinnati Steel Treating performs induction hardening heat treatments for a number of different applications on a wide variety of steel parts. We have induction hardened everything from shafts to brackets to powder metallurgy gears.

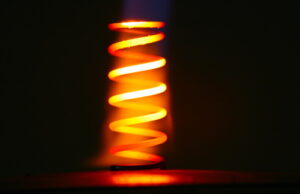

Cincinnati Steel Treating is an industry leader in induction hardening. Induction hardening is a process where an electric current is “induced” into a ferrous part through energized magnetic coils that surround the area to be heat treated. Resistance to the flow of this induced current is what creates heat in the area to be treated. Induction hardening is typically used as a surface hardening heat treatment. A hardened case with a specific depth of hardness is produced at a specific location on a steel or cast iron part. Allow our expertise and existing relationships in the induction hardening industry benefit you. Our partnerships include induction hardening machine manufacturers, coil manufacturers, and induction tooling fabricators. We have the edge in designing optimized induction hardening heat treatments.

Cincinnati Steel Treating is an industry leader in induction hardening. Induction hardening is a process where an electric current is “induced” into a ferrous part through energized magnetic coils that surround the area to be heat treated. Resistance to the flow of this induced current is what creates heat in the area to be treated. Induction hardening is typically used as a surface hardening heat treatment. A hardened case with a specific depth of hardness is produced at a specific location on a steel or cast iron part. Allow our expertise and existing relationships in the induction hardening industry benefit you. Our partnerships include induction hardening machine manufacturers, coil manufacturers, and induction tooling fabricators. We have the edge in designing optimized induction hardening heat treatments.

Trust your Induction Hardening Needs to our Experts

Induction Hardening vs. other Heat Treatments

Induction Hardening offers many advantages. It is primarily a surface hardening heat treatment that is used to produce hardness on a specific area of a part. It typically produces less distortion and the distortion that is produced is more predictable. It is very fast with treatments taking anywhere from a few seconds to a minute. It is very good for applications where there is a requirement to keep areas outside of the heat treated

Induction Hardening Capabilites

Cincinnati Steel Treating (CST) has three Induction Hardening machines capable of heat treating parts. We identify these machines as the Zion, the Tocco, and the Radyne. The dimensional capabilities of both machines are highlighted in the two tables below:

Cincinnati Steel Treating (CST) has three Induction Hardening machines capable of heat treating parts. We identify these machines as the Zion, the Tocco, and the Radyne. The dimensional capabilities of both machines are highlighted in the two tables below:

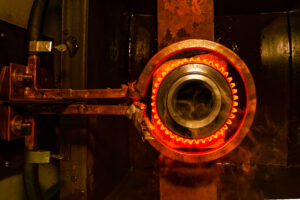

Induction Hardening Applications

Cincinnati Steel Treating (CST) has a great deal of experience performing induction hardening. Most applications involve heat treating a targeted area on a section of a medium carbon alloy steel shaft (4140, 4340, 4130). Other examples of parts that are induction hardened include crankshafts, cam shafts, spindles, and round bars with splines cut into the OD. Gears and gear teeth are also commonly induction hardened. Inductiond hardening is adaptable. Special coils can be designed to heat treat a specific area and leave the remainder of the part unaffected. Tempering and annealing can be performed using induction as well.

Cincinnati Steel Treating (CST) has a great deal of experience performing induction hardening. Most applications involve heat treating a targeted area on a section of a medium carbon alloy steel shaft (4140, 4340, 4130). Other examples of parts that are induction hardened include crankshafts, cam shafts, spindles, and round bars with splines cut into the OD. Gears and gear teeth are also commonly induction hardened. Inductiond hardening is adaptable. Special coils can be designed to heat treat a specific area and leave the remainder of the part unaffected. Tempering and annealing can be performed using induction as well.

Bring Us Your Induction Hardening Challenges

For over 80 years, we’ve helped our clients across many industries improve production time and parts performance, quickly and efficiently. Turnaround times are fast and quality control is precise. As your outsourcing partner, we provide solutions to take your results to the next level.